Tile Tips

The Case for One-Direction Troweling

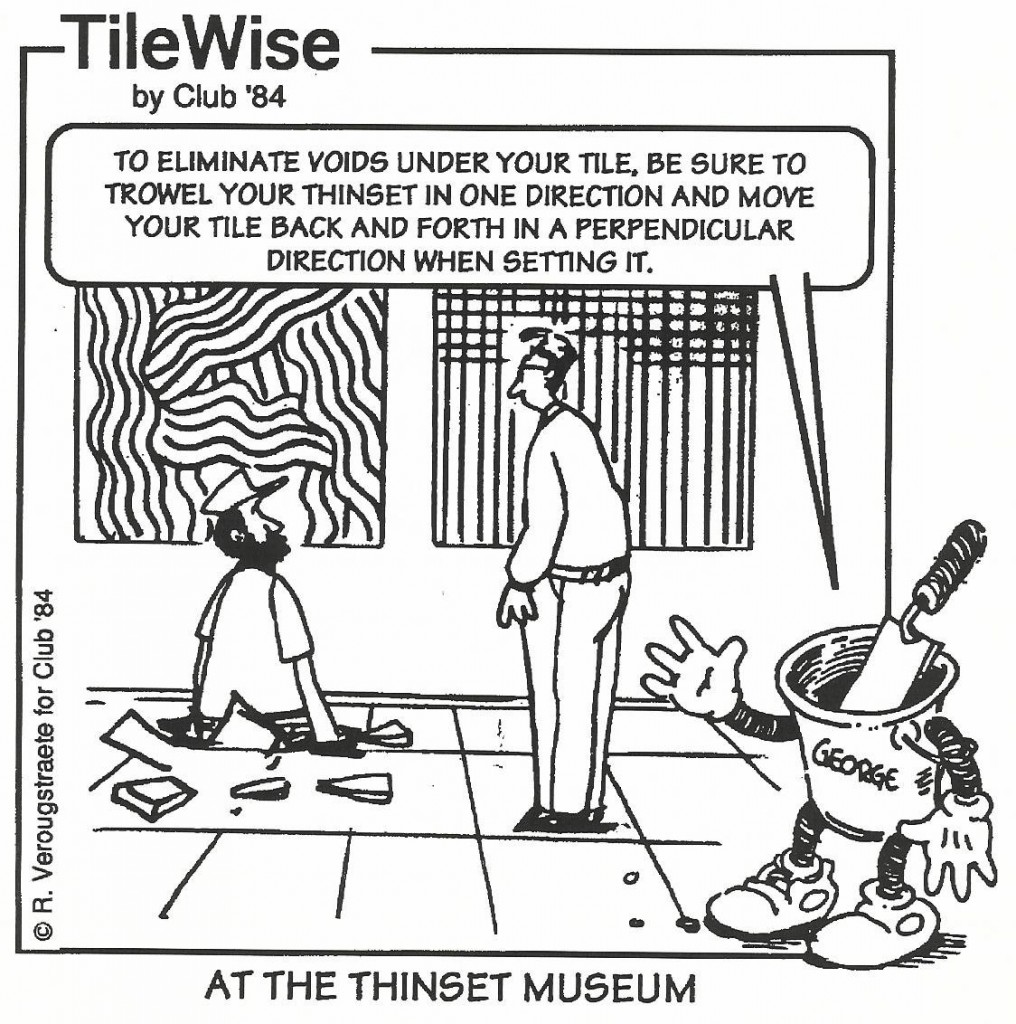

Current thin-set standards require a minimum of 80% thin-set contact for interior dry applications. For exterior or interior wet applications the requirement is 95% contact. Contact means that the thin-set is in continuous contact between the back of the tile and its substrate. The standards say that within the allowable 5% or 20% voids respectively, there can be no void larger than 2 square inches, and that all corners and edges of the tile have to be fully supported with thin-set (no voids). To achieve full thin-set contact can be difficult particularly on large format tiles. Air can get trapped under the tile and no matter how much thin-set you use or how much you beat the tile in, the air in those voids can’t escape. A recommended method to achieve full thin-set contact is to trowel in one direction, after you have burned/keyed the thin-set into the substrate/tile. If you trowel on both the back of the tile and the substrate, make sure those trowel lines are parallel to each other when you set the tile on the substrate. Once you set the tile on the substrate then press it firmly into the thin-set and move the tile perpendicular to the direction of the trowel ridges, at least a 1/4″ or so, to flatten the ridges of the thin-set and collapse it into the valleys of the thin-set. This allows the air in the valleys of the thin-set to escape from the sides of the tile. If you try this with a clear glass or plexiglass tile you will see how effective it is compared to troweling in an irregular pattern.